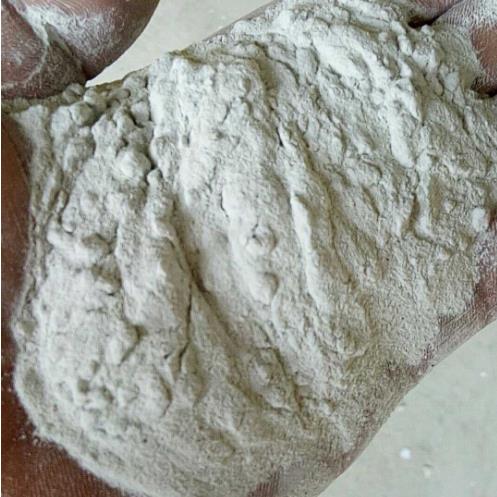

Automatic PE Plastic Pulverizer has the characteristics of high output and low energy consumption. It can be widely used for powder processing of low pressure polyethylene HDPE, high pressure polyethylene LDPE, linear polyethylene LLDPE, polycarbonate PC, polystyrene PS, butyl styrene ABS, foamed PE, SBS, wood plastic, leather and other materials .

Points to pay attention to when using PE plastic Pulverizer:

1: The hardness of the material: the higher the hardness of the material, the more difficult it is to grind, and the greater the loss of equipment parts.

2: Material temperature: The water content in the grinding material should not exceed 20%. If the water content of the PVC mill is too high, the particle size of the grinding disc will be larger, and the discharge pipe and suction fan will be easily blocked.

3: The fineness of the material: the higher the fineness of the grinding material, the lower the output, and the loss and load of the equipment are the same.

4: Components of the material: The components of the PE mill material should be checked before grinding. Among them, the viscosity is high or the melting point is too low, and the density should be distinguished.

5: Bearing temperature: under normal production conditions, check whether the cooling water of the bearing seat is turned on, whether the water temperature is normal, and whether the high-temperature lubricating oil is added.

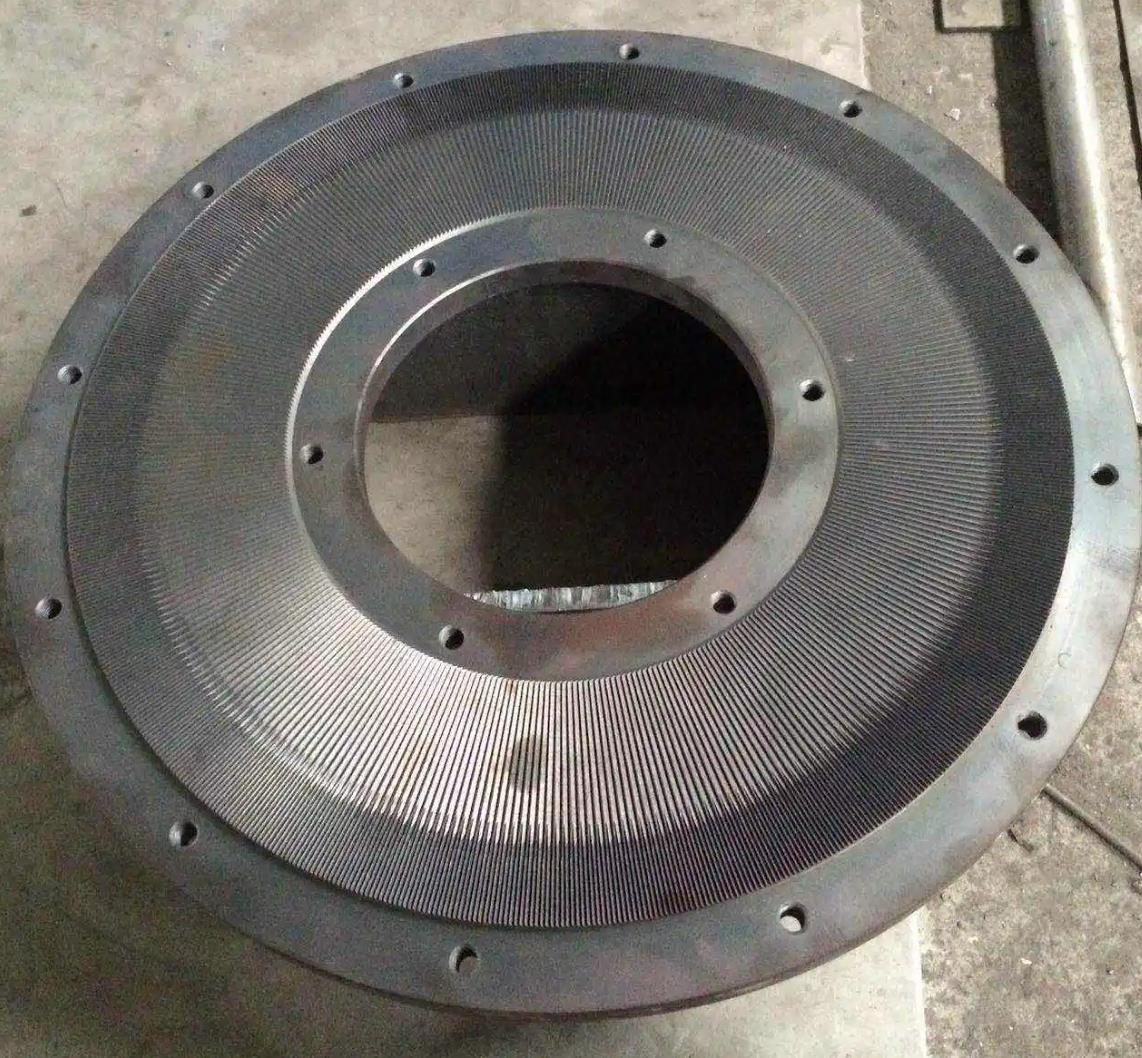

6: The hardness and material of the grinding disc.