High – Performance FRP Fiberglass Rebar Pultrusion Caterpillar Pulling Machine

Elevate your FRP (Fiberglass Reinforced Plastic) rebar production to a new level of efficiency and precision with our state – of – the – art FRP Fiberglass Rebar Pultrusion Caterpillar Pulling Machine. Tailored specifically for the seamless manufacturing of GFRP (Glass Fiber Reinforced Plastic) rebars and fiberglass rock bolts, this machine stands as a reliable cornerstone for your production line, combining robust construction, advanced technology and user – friendly design to meet the rigorous demands of modern construction material manufacturing.

Unmatched Core Performance

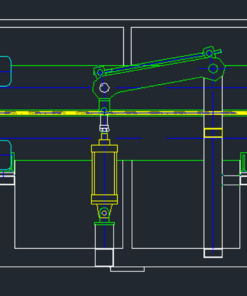

At the heart of this machine lies a powerful 2.2kW dual – motor system. Unlike single – motor alternatives, the dual – motor configuration delivers balanced, consistent and formidable traction force. It ensures smooth and uniform pulling of FRP rebar during the pultrusion process, eliminating issues such as uneven tension that can compromise the structural integrity of the final products. The motors are engineered for energy efficiency and long – term stable operation, reducing energy consumption while maximizing productivity—an essential advantage for both small – scale workshops and large – scale production facilities.

Complementing the strong motor system is the 3500mm – long traction frame. This extended length is a game – changer for FRP rebar production. It provides an ample and stable supporting platform for the rebar during the pulling stage, allowing for better control over the product’s straightness and dimensional accuracy. Whether you are producing standard – length FRP rebars for general construction or customized fiberglass rock bolts for tunnel and mining projects, the 3500mm traction frame accommodates various production needs, minimizing material waste and enhancing overall product quality.

The caterpillar – style pulling mechanism is another highlight. It features high – grip, wear – resistant caterpillar tracks that securely hold the FRP rebar without causing surface damage. The synchronized movement of the caterpillar system guarantees constant pulling speed, which is crucial for maintaining the uniform resin content and fiber arrangement of FRP rebars—key factors that determine their tensile strength, corrosion resistance and durability, properties that make FRP rebars a superior alternative to traditional steel rebars in harsh environments.

Exceptional Versatility & Durability

This machine is not just limited to a single type of FRP rebar production. It is highly adaptable to different specifications of GFRP rebars and fiberglass rock bolts, supporting adjustments for varying diameters and lengths to meet diverse project requirements, from small – diameter rebars for residential construction to heavy – duty rock bolts for geotechnical engineering.

Constructed with high – quality steel and wear – resistant components, the machine is built to withstand the rigors of continuous industrial operation. The frame undergoes precision welding and anti – corrosion treatment, ensuring a long service life even in the dusty and humid conditions common in production workshops. Routine maintenance is simplified with easily accessible components, reducing downtime and keeping your production line running smoothly.

Why Choose Our Machine?

- Superior Product Quality: The combination of dual – motor traction and a 3500mm frame ensures every FRP rebar and fiberglass rock bolt meets strict industry standards, boosting your product’s market competitiveness.

- Cost – Effective Operation: Energy – saving dual motors and low maintenance requirements cut down on long – term operational costs, while high production efficiency increases your profit margins.

- Reliable After – Sales Support: We provide comprehensive technical guidance, installation assistance and spare parts supply to ensure you get the most out of your investment.

Ideal Application Scenarios

Perfectly suited for manufacturing FRP rebars and fiberglass rock bolts used in:

- Infrastructure projects such as bridges, highways and coastal engineering (thanks to FRP’s excellent corrosion resistance to saltwater and chemicals).

- Tunnel, mining and geotechnical engineering, where fiberglass rock bolts offer reliable reinforcement and long service life in complex underground environments.

- Precast concrete component production, where high – precision FRP rebars enhance the quality and performance of precast parts.

- Construction projects in corrosive environments, including chemical plants and wastewater treatment facilities, where traditional steel rebars are prone to rust and degradation.

Upgrade your FRP rebar production capacity today. Our FRP Fiberglass Rebar Pultrusion Caterpillar Pulling Machine is more than just a piece of equipment—it is a strategic investment that drives your business forward. Contact us now to get a detailed quotation, request a live demonstration or discuss customized solutions