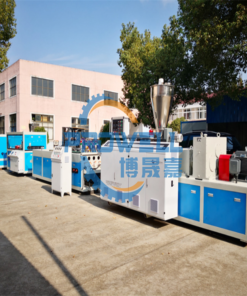

Equipment overview

16-32mm PVC Pipe Four Cavity Production Line is used for pipe production line extrusion molding. PVC formula material is fed into the barrel by a feeding screw quantitatively, and the material is conveyed, compressed, plasticized and metered by the screw, and then enters the forming mold. The material of the barrel and screw of this machine is 38CrMoAlA, which has been forged, quenched and tempered, twice aging treatment, and nitriding treatment.

What is different from other manufacturers is our PVC Pipe Four Cavity Production Line the screw edge is rough-processed and quenched and tempered, and the material has excellent hardenability, and the effective stress is obtained after two aging treatments. At the same time, the machining is excellent, and the phase error of each section of the screw is small. The barrel and screw are interchangeable. For different materials, the screw structure is all changed. The gearbox distribution box is composed of hard-faced gears with high precision and fatigue resistance. The material of the reduction box gear is 20CrMnTiA, which has been carburized, and the helical gear of the distribution box is made of 38CrMoAlA, which is formed by CNC gear hobbing and nitriding.

Product Paramenters

| Model/Item | Pipe range | Extruder | Max output | Max speed | Total power |

| PVC-50*2 | 16-50mm | SJSZ65/132 | 250kg/h | 10 m/min | 85 kw |

| PVC-63 | 16-63mm | SJSZ51/105 | 150 kg/h | 10 m/min | 60 kw |

| PVC-110 | 50-110mm | SJSZ55/110 | 180 kg/h | 10 m/min | 70 kw |

| PVC-160 | 63-160mm | SJSZ65/132 | 300 kg/h | 5 m/min | 90 kw |

| PVC-250 | 110-250mm | SJSZ80/156 | 400 kg/h | 3.5 m/min | 120 kw |

| PVC-315 | 160-315mm | SJSZ80/156 | 400 kg/h | 3 m/min | 160 kw |

| PVC-450 | 250-450mm | SJSZ92/188 | 700 kg/h | 1.5 m/min | 200 kw |

| PVC-630 | 315-630mm | SJSZ92/188 | 700 kg/h | 0.9 m/min | 230 kw |