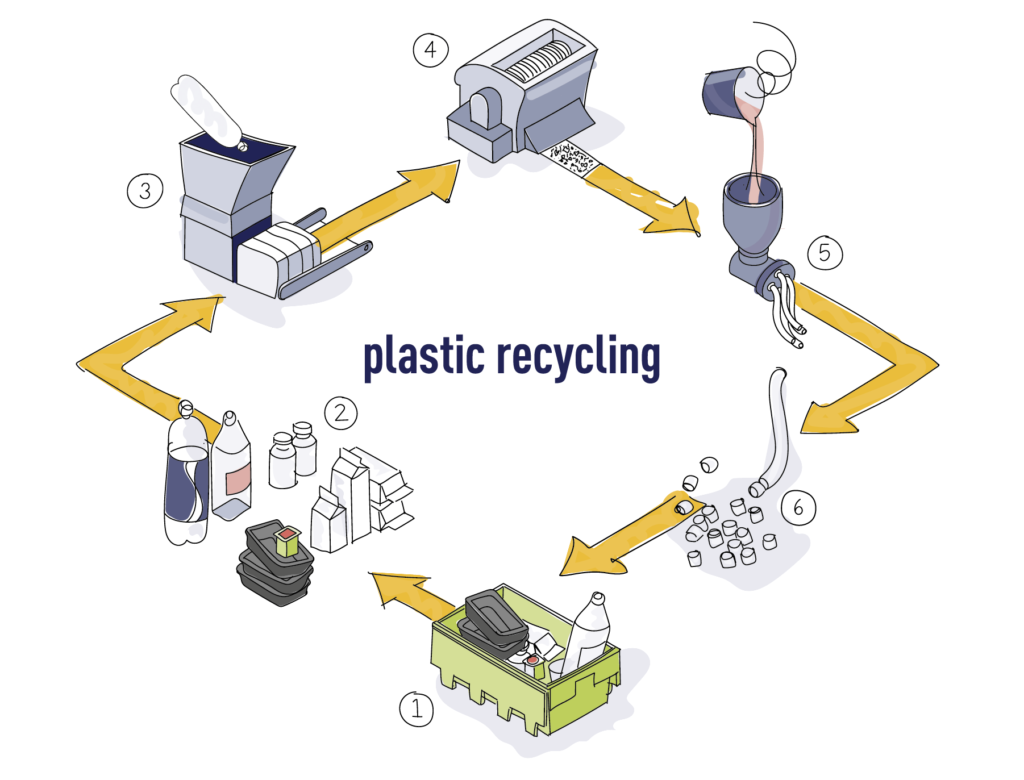

PVC Waste Material Recycling For the discarded PVC products in daily life and industrial and agricultural applications, first remove the non PVC products, then classify them according to the hard and soft properties of PVC products. And finally add an appropriate amount of additives through granulation, extrusion and other methods

In this cycle, the sorted PVC waste material can also be dried and crushed, and then ground into recycled powder.

The properties of Recycled PVC plastic are very close to that of original PVC plastic. But the price is 20% – 30% lower.

The recycle waste PVC products (agricultural film, furniture, oil bottle, mineral water bottle, packaging film, etc.) have been used as raw materials for making pipes, rain proof materials, household appliances, elastic floors, wall decorative panels, etc.

The modified regeneration of modified recycled waste plastics is to modify the recycled materials by physical and chemical methods and then process them.

Physical modification of waste plastics refers to the preparation of multicomponent blends by mixing. Filling, fiber compounding and blending toughening are the main means of physical modification of PVC.

PVC filling materials mainly use inorganic, metal, gas and so on as fillers to modify PVC. Filling modification not only has the most effect, but also has the effect of modification. It can improve the hardness, stiffness, heat resistance, flame retardancy of products, and reduce the cost.