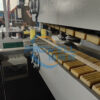

Unleash Efficiency with Our Glassfiber Rebar Caterpillar Pultrusion Machine

Elevate your pultrusion process to unprecedented levels of speed and precision with our cutting-edge GFRP Rebar Pultrusion Haul-off Machine. Designed to exceed industry standards, this machine is your key to seamless production and enhanced project timelines.

| DY-2 Caterpillar Haul off Machine | ||

| 1 | Haul off frame total length | 3000mm/3500mm/4000mm |

| 2 | Motor Power | 2.2KW Cycloid reducer*2 |

| 3 | Torque | 2000N.M |

| 4 | Transfer method | Sprocket transmission |

| 5 | Speed | 1 ~ 2.5m/mim / 1-5m/min |

| 6 | Traction frame clamping method | Pneumatic compression/opening |

| 7 | Traction Block material | Rubber Type |

| 8 | Rubber Type Size | customizable |

| 9 | Rubber Block Hardness | 70-75 degree |

| 10 | Frame structure | Rectangular steel welded |

| 11 | Traction center height | 1000mm. Adjustable |

Key Features:

Optimized Traction Control: Our Haul-off Machine ensures precise traction control, allowing for the smooth and steady extraction of GFRP rebars from the pultrusion die. Minimize disruptions and achieve consistent results with every pull.

Adjustable Speed Settings: Tailor the haul-off speed to match the specific requirements of your production process. Whether you need rapid extraction or a more controlled pace, our machine adapts to your needs.

Durable Belt System: Built for longevity and reliability, our Haul-off Machine features a robust belt system that can withstand the demands of continuous operation. Experience minimal downtime and maximum productivity.

User-Friendly Interface: Streamline your operations with an intuitive user interface that allows for easy adjustments and real-time monitoring. Empower your team to operate the machine with confidence.

Benefits:

Enhanced Production Speed: The Glassfiber Rebar Caterpillar Pultrusion Machine is engineered for efficiency, significantly reducing the time required for the extraction of pultruded GFRP rebars. Boost your production output without compromising quality.

Consistent Quality: Achieve uniformity in your GFRP rebar production with our machine’s precision traction control. Say goodbye to variations and hello to a standardized, high-quality end product.

Adaptable to Various Rebar Specifications: Whether you are working with different diameters or lengths of GFRP rebars, our machine effortlessly adapts to meet your specific project requirements. Enjoy flexibility without sacrificing efficiency.

Low Maintenance Requirements: Benefit from a hassle-free maintenance experience. Our Haul-off Machine is designed for durability and ease of upkeep, ensuring that your production line remains operational with minimal disruptions.

Choose Efficiency, Choose Our GFRP Rebar Pultrusion Haul-off Machine:

Proven Performance: Backed by rigorous testing and real-world application, our machine has proven its worth in diverse construction settings. Trust in a solution that delivers consistent results.

Expert Support: Our commitment to your success goes beyond the sale. Access expert support from installation to ongoing maintenance, ensuring that you get the most out of your investment.

Future-Ready Technology: Embrace the future of construction with a Haul-off Machine that integrates seamlessly into modern manufacturing processes. Stay ahead of the curve with our innovative technology.

Transform your pultrusion process and experience a new era of efficiency. Contact us today to explore how our GFRP Rebar Pultrusion Haul-off Machine can revolutionize your production line.