Glass Fiber Reinforced Rebar FRP Support Anchor Pultrusion Production Line: Unleashing Efficiency with Advanced Rubber Type Traction & Cutting Tech

In the demanding world of manufacturing Glass Fiber Reinforced Polymer (GFRP) rebar for support anchors, achieving consistent quality, high throughput, and precise dimensional control is paramount. The heart of a superior pultrusion line lies in its traction and cutting systems. Our cutting-edge Rubber Type Traction Machine and Cutting Machine are engineered to deliver unparalleled performance, directly translating to superior FRP support anchor products and optimized production. Discover the technological advantages that set this line apart.

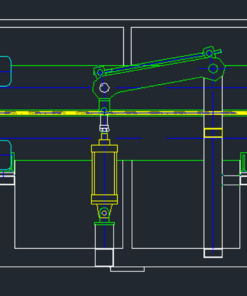

Dominating Traction: The Power of the 3-Meter Rubber Type Traction Machine

Forget subpar traction compromising your FRP profiles. Our Rubber Type Traction Machine is engineered for maximum grip, stability, and control, specifically optimized for demanding GFRP rebar production:

Unmatched 3-Meter Traction Grip: Experience the critical advantage of an exceptionally long 3-meter traction frame. This extended contact surface distributes gripping force far more evenly along the profile compared to shorter systems. The result? Significantly reduced profile distortion, enhanced surface integrity, and superior dimensional consistency – crucial for the structural performance of FRP support anchors.

Precision Speed Control with Variable Frequency Drive (VFD): Gain complete command over your line speed. The integrated VFD enables smooth, infinitely variable speed adjustment. Easily optimize pulling rates for different resin systems, profile sizes, or curing requirements, maximizing output without sacrificing quality.

Dual Material Flexibility (Silicone or Rubber): Tailor traction to your specific needs. Choose durable standard rubber blocks for robust performance or opt for high-temperature silicone blocks when processing requires elevated cure temperatures. This flexibility ensures optimal grip and block longevity across diverse production scenarios.

Robust Dual-Motor Drive & Synchronized Power: Experience unwavering pulling force. Powered by twin 2.2kW motors, this system delivers exceptional torque. Crucially, the chain synchronous transmission ensures perfectly synchronized power delivery to both sides of the traction mechanism. This eliminates differential slippage and guarantees straight, stable pulling – fundamental for producing high-tolerance FRP rebar.

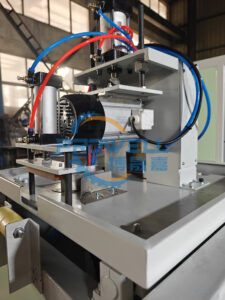

Precision Cutting Redefined: Intelligent, Clean, Automated Cutting

Transform the final step of your FRP support anchor production. Our advanced Cutting Machine delivers clean, precise, and dust-free cuts with minimal operator intervention:

Superior Cut Quality with Twin Blade Action: Achieve clean, burr-free ends essential for anchor functionality. The upper and lower saw blade configuration cuts simultaneously from both sides, minimizing material stress and ensuring a superior finish on the tough GFRP rebar.

Moving Table Technology for Flawless Cuts: Eliminate drag and potential profile damage during cutting. The innovative moving table travels synchronously with the profile as the cut is made. This ensures zero relative movement between the blade and the rebar, guaranteeing perfectly square, distortion-free cuts every time. The table then automatically retracts seamlessly to the start position.

Integrated Water Spray Dust Suppression: Maintain a clean, safe, and compliant workshop. The built-in water spray system effectively suppresses dust generated during cutting. This protects operator health, improves visibility, reduces machine wear, and meets environmental standards. The self-contained water tank and pump ensure continuous operation without external plumbing hassles.

Pinpoint Accuracy with Limit Switch Control: Achieve absolute precision in every anchor length. Limit switches enable precise “set and forget” length control. The system automatically triggers the cut at the exact pre-programmed point, guaranteeing consistent anchor lengths critical for structural applications and eliminating manual measurement errors.

The Synergistic Advantage: Your Path to Premium FRP Support Anchors

Integrating this high-performance Rubber Type Traction Machine and Cutting Machine into your GFRP rebar pultrusion line delivers transformative benefits:

Enhanced Product Quality: The long traction grip and synchronized pull minimize distortion, ensuring straight, dimensionally accurate rebar with superior surface quality. Precise, clean cuts maintain structural integrity at the ends.

Increased Production Efficiency: VFD speed control optimizes line throughput. Automated, precise cutting eliminates manual measuring and reduces cycle times.

Reduced Waste & Cost: Consistent pulling and exact cutting minimize material waste from scrap ends or out-of-spec profiles.

Improved Operational Safety & Environment: Effective water spray dust suppression creates a cleaner, healthier workplace.

Greater Process Control & Flexibility: Adapt easily to different profiles and production requirements with variable speed and material choices.

Invest in Precision. Invest in Performance.

Elevate your Glass Fiber Reinforced Rebar FRP Support Anchor production to new levels of quality, efficiency, and reliability. Our advanced pultrusion line, featuring the 3-meter Rubber Type Traction Machine with VFD control and dual-material options, coupled with the intelligent Moving Table Cutting Machine featuring dust suppression and limit switch precision, provides the technological edge you need. Experience the difference that purpose-built, high-performance equipment makes.

Ready to optimize your FRP support anchor manufacturing? Explore the power of precision traction and cutting today!

Glass Fiber Reinforced Rebar FRP Support anchor pultrusion Production Line Rubber Type Traction Machine and Cutting Machine